.

Cryogenic Extraction: A Cool Form of Cannabis Processing

Cryogenic cannabis extraction is an effective way to preserve terpenes, maximise purity, and keep out contaminants. However, there are barriers to its widespread use, especially among amateur concentrate makers. Here, we're looking at the pros and cons of the cryogenic extraction method for weed.

There are countless ways to create cannabis extracts these days—with and without solvents. Each method has its pros and cons and claims to be somehow superior to the rest. One such method is cryogenic extraction, which uses sub-zero temperatures to unlock the full potential of cannabis plants.

In this guide, we’ll explore the science behind cryogenic extraction, its benefits, the equipment needed, and how it compares to traditional extraction techniques.

What Is Cryogenic Extraction?

Cryogenic extraction is a cutting-edge technique used in the cannabis industry to preserve delicate compounds and improve extract purity. It is a challenging process, but the payoff is that you get an extremely high-quality cannabis product that retains many of the terpenes found in the unprocessed, raw plant.

Unlike conventional extraction methods, cryogenic extraction involves processing cannabis plant material at extremely low temperatures, most often using cryogenic ethanol.

There are some key advantages to the cryogenic extraction method:

- Preserves delicate compounds: Cannabinoids and terpenes, which degrade under heat, remain intact.

- Reduces oxidation and degradation: The sub-zero temperatures minimise chemical reactions that can compromise extract quality.

- Enhances purity: Fewer unwanted compounds make their way into the final product, resulting in a cleaner extract.

How Does Cryogenic Extraction of Cannabis Work?

Cryogenic extraction follows a controlled, step-by-step process to ensure efficiency and purity. The process itself isn’t overly complicated, but some of the ingredients and equipment needed are difficult to acquire and handle, and as such it can be considered an advanced cannabis extraction process.

Below, we’ll outline how to cryogenically extract weed.

Step 1: Freezing the Plant Material

First, the cannabis must be rapidly frozen at sub-zero temperatures. This is achieved using one of three methods, which are outlined below.

This initial step is essential as it prevents degradation of delicate compounds like terpenes and cannabinoids. Freezing also makes the plant material brittle, reducing the presence of undesirable plant waxes, fats, and chlorophyll in the final extract.

Here’s how cannabis is frozen to prepare for cryogenic extraction:

- In a commercial, ultra-low-temperature freezer: These sit between -40 and -80ºC and are the most common way to cryogenically freeze cannabis.

- Using liquid nitrogen: Cannabis can be flash-frozen by being submerged in liquid nitrogen (-196ºC) for a couple of seconds. Due to the volatile nature of this material and the difficulty in handling it, though, this is not the most common method of freezing.

- Dry ice: This is used in smaller-scale operations where access to the above two options is not possible. The plant material is placed inside an insulated container with dry ice (-78.5ºC), which rapidly cools the surrounding air.

Step 2: Cryogenic Solvent Application

After the initial freezing, a cryogenic solvent, most commonly ethanol, is chilled to ultra-low temperatures and used to extract cannabinoids and terpenes. The frozen plant material is then submerged in the cryogenic ethanol, allowing the solvent to dissolve active compounds like THC, CBD, and terpenes. The mixture is agitated to maximise extraction efficiency.

At -80°C or lower, ethanol acts as an efficient solvent that selectively dissolves desirable compounds while leaving behind unwanted plant material.

Step 3: Filtration

The ethanol solution is now subjected to multiple filtration stages to remove solid plant material, waxes, and other impurities.

The extreme cold temperatures prevent excessive extraction of chlorophyll, which can lead to unwanted bitter flavours and a green tint in conventional ethanol extraction.

Step 4: Solvent Recovery and Concentrate Refinement

Once the cannabinoids and terpenes are dissolved into the cryogenic solvent, the ethanol is separated and recovered through vacuum evaporation or rotary evaporation. Low-pressure and low-temperature distillation methods help to retain the maximum amount of cannabinoids and terpenes without degrading them. The final concentrate is then further purified or refined, depending on the intended product type:

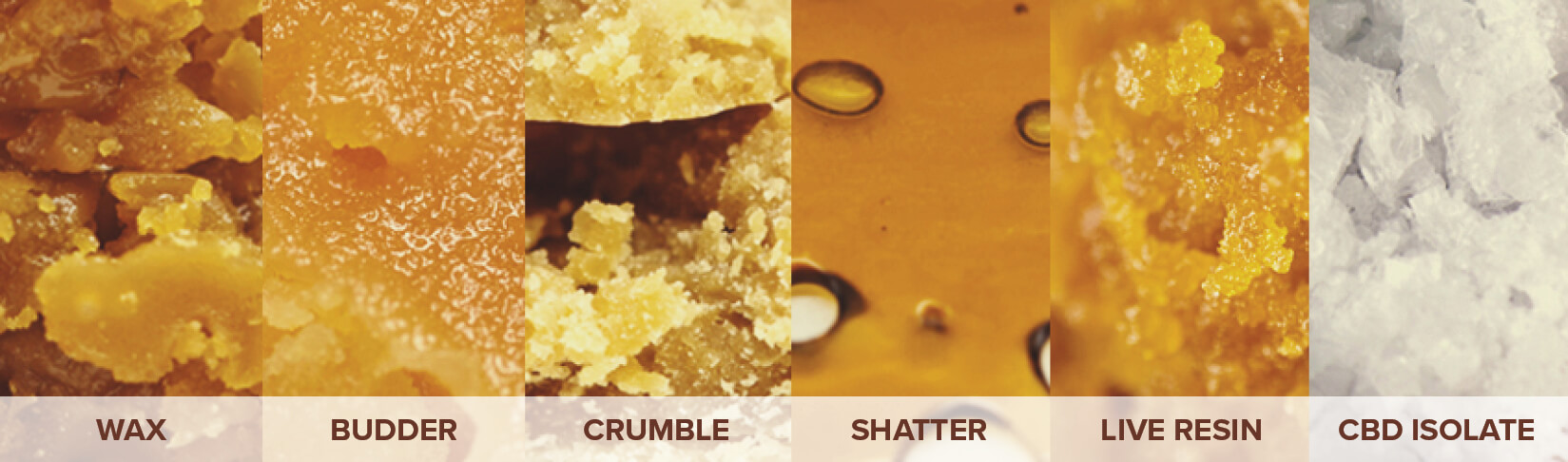

• Full-spectrum extract (preserves a wide range of cannabinoids and terpenes)

• Distillate (high-purity cannabinoid oil with minimal terpenes)

• Isolate (pure cannabinoid, such as CBD or THC)

Step 5: Post-Processing and Product Formulation

The purified extract can be used to create various cannabis products, such as:

Vape cartridges (i.e. high-terpene extracts)

Edibles and tinctures (these require decarboxylation to activate cannabinoids)

Concentrates like shatter, wax, or live resin (i.e. high-potency extracts with rich flavour profiles)

Benefits of Cryogenic Extraction for Cannabis

Beyond sounding futuristic, there are numerous advantages to using cryogenic extraction to make cannabis products. Chiefly they pertain to quality, so cryogenic weed can generally be considered very pure and of high quality.

-

Terpene Preservation

Traditional extraction methods expose terpenes to heat and oxygen, causing them to degrade. As a result, the consequent cannabis products tend to lack a distinct flavour that truly represents the chemical profile of the original plant material.

If you’ve spent months carefully growing a particular phenotype because of its terpene profile, it’s a shame to lose it at this later stage. Cryogenic temperatures prevent terpene loss, ensuring a more aromatic and flavourful extract.

-

High Extraction Efficiency

Cryogenic extraction maximises cannabinoid yield while reducing unwanted plant material. All extraction methods involve some material loss, but cryogenic techniques significantly reduce it.

The cold environment improves solubility, leading to more efficient compound separation. As a consequence, most of the desired material is carried over from the plant material, while most of the undesired material is left behind.

-

Cleaner Final Products

Building on the previous point, impurities are left behind! This is true of unwanted parts of the plant, and also for potential impurities introduced during the extraction process. The freezing doesn’t introduce impurities, and while the solvent does, it is minimal due to the nature of the process.

Moreover, reduced exposure to high temperatures and oxidation minimises contamination risks, and extracts produced via cryogenic methods require less post-processing and refinement.

-

Reduced Oxidation

Cold temperatures significantly slow down oxidation, extending the shelf life of extracted compounds. This results in a product with better stability and consistency.

Cryogenic vs Traditional Extraction Methods

Cryogenic extraction offers distinct advantages over methods such as supercritical CO₂ and traditional ethanol extraction, particularly that it retains so many of the heat-sensitive compounds in cannabis. Below is a table comparing the process, efficiency, terpene preservation, and complexity of each.

| Cryogenic Extraction | |

| Temperature | -80°C to -196°C |

| Efficiency | High |

| Terpene Preservation | Excellent |

| Operational Complexity | Moderate |

| CO₂ Extraction | |

| Temperature | 31°C to 40°C |

| Efficiency | Moderate |

| Terpene Preservation | Moderate |

| Operational Complexity | High |

| Ethanol Extraction | |

| Temperature | Room temperature |

| Efficiency | High |

| Terpene Preservation | Low |

| Operational Complexity | Low |

| Factor | Cryogenic Extraction | CO₂ Extraction | Ethanol Extraction |

| Temperature | -80°C to -196°C | 31°C to 40°C | Room temperature |

| Efficiency | High | Moderate | High |

| Terpene Preservation | Excellent | Moderate | Low |

| Operational Complexity | Moderate | High | Low |

Safety Considerations for Cryogenic Extraction

Working with cryogenic substances is dangerous, and as such requires strict safety protocols if you’re to avoid accidents. Here are the key precautions to take when handling these substances.

Protective Gear

Operators handling cryogenic solvents at ultra-low temperatures must wear specialised protective gear to prevent injuries from frostbite, burns, and exposure to hazardous substances. The following pieces of cryogenic extraction equipment are essential when creating cryogenic weed:

- Insulated gloves

- Face shields and safety goggles

- Cryogenic aprons and lab coats

- Closed-toe, insulated footwear

Proper Ventilation

Cryogenic solvents can release potentially hazardous vapors, so it’s important to operate in an environment that’s well ventilated in order to maintain a good, steady flow of fresh air. Given that you might be operating in enclosed spaces, it’s important to create airflow through means such as fume hoods, exhaust systems, and, at the most basic, open windows.

This is paramount because cryogenic solvents can displace oxygen, creating an asphyxiation hazard if used in small, unventilated rooms.

Equipment Maintenance

Cryogenic extraction systems rely on precision-engineered equipment that must be regularly inspected and maintained to ensure safe and efficient operation. Malfunctions can lead to leaks, temperature fluctuations, or hazardous pressure build-ups.

Training

Due to the specialist nature of the equipment and chemicals involved in creating cryogenic weed, proper training is essential for all personnel operating cryogenic extraction systems. Handling supercooled solvents at extreme temperatures requires specialised knowledge to prevent accidents.

Is Cryogenic Extraction Worth the Investment?

All this effort begs the question, is cryogenic weed worth it? Well, it depends. It’s certainly a safe and very effective method of producing cannabis extracts, but it’s not the most feasible option for non-commercial projects.

If you’re looking to create top-quality cannabis concentrates at home, then you should probably look to easier and more accessible options than cryogenic extraction, such as making rosin or bubble hash. But for large-scale projects, it can be worth the time, energy, and money required to create a quality final product. Much of it comes down to scalability.

-

Cost Analysis

This extraction method comes with a high initial investment. This is in part due to the necessary equipment, and in part due to the training. Over time, this investment can be returned if an operation creates enough high-quality extract, but this isn’t really sensible for personal projects.

-

Use Cases

If the end goal is to create a high-end commercial cannabis product with fantastic purity and terpene retention, then cryogenic extraction is certainly a suitable candidate. If the goal is simply a safe extract with respectable purity, potency, and flavour, then there are easier and less-expensive methods available.

-

Scalability

While it’s not really suitable for personal projects, this method is scalable, and thus can be adjusted to projects of varying sizes. You don’t have to be a large corporation to utilise cryo extraction—small-scale, specialised labs can also leverage the benefits, provided they have the right equipment and training. However, the smaller the project, the less practical and viable this type of extraction becomes.

Final Thoughts: Is Cryogenic Extraction the Future of Cannabis Processing?

By preserving terpenes, improving efficiency, and delivering cleaner extracts, cryogenic extraction provides a novel and extremely effective method of producing high-quality cannabis concentrates. That being said, it is not the only way to create pure, unadulterated products, and there are more straightforward avenues that are totally solventless. With that said, while cryo extraction will play a role in the future of cannabis, it is unlikely to be the sole solution.